Architectural Description:

Square facade; many wings

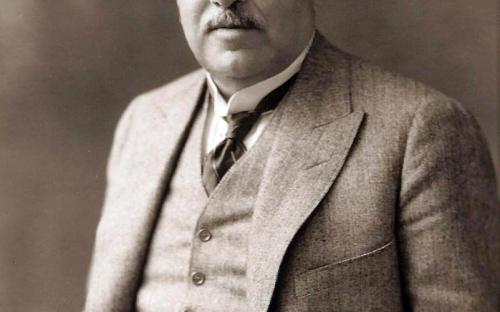

The mill complex was designed by Winfield Bradford Knowlton of Boston, built by Turner Construction Company.

Winfred Knowlton moved to Andover, residing at 69 Salem St.

June 1990, Andover Preservation Award for Contextual Rehabilitation to Bricksotne Square

Historical Narrative:

Themes: Architectural, Commerce, Community development, Industry

Original owner: American Woolen Company - 1920 - 1956

Later owners: Raytheon Corporation 1956 -1971, Shetland Properties Andover 1971-1986, Andover Mills Realty Limited Partnership 1986-1990, Andover Mills LLC 1990 - 2005, ASLAN III Brickstone Square. 2005 - 2014, New Brickstone Square 2014 -

AT - Sept. 3, 1920 – Work On Bridge Begun – Construction of bridge and warehouse started in Shawsheen

Village on Monday. ......Turner Construction to build new warehouse – 300’ long 3 stories high on the south side of Argyle. Argyle St. runs from the River to the tracks of the B& M RR and is parallel to Haverhill Street. This street was built and named Argyle St. in error. Eight houses were built along the north side of the road leading into Mill #1. When Mr. Wood returned form a European tour on Sept. 10, 1921 he saw the street, and is reported to have pointed his cane and said, "Remove those houses immediately!" The homes were then moved to the upper north end of York St.

Historical significance:

This industrial complex includes 2 five-story spinning and weaving mills connected at eastern ends, a dye house, and a 10-story warehouse building - "not only the last word in mill construction, but beyond a doubt the finest textile mill in the world" (Shawsheen: A Model Community).

It was erected at the cost of $1,000,000. 1400 mill operatives were employed here but it represented only one of William Madison Wood's 63 textile mills of the American Woolen Company. Considered a model mill - it was powered by electricity produced at Shawsheen power plant on Shawsheen River. Continued until 1950's when sold to number of smaller industries.

Dec. 23, 1921 Andover Townsman - Progress at Shawsheen Mills -

Work on installing machinery in the new Shawsheen Mill is progressing rapidly. Shipments of both domestic and foreign machines have already arrived and are being assembled and placed in position by a large force of men whose work to the uninitiated seems to be a continual Chinese puzzle.

In line with the policy of the company to promote to higher positions men within the organization whenever possible, the new mill has meant promotions for many of our fellow workers.

Thomas Bredbury, since 1912 Superintendent of the French Spinning Department of the Wood Mills has been appointed Agent of the new plant. This well-earned promotion comes after many years of service in the American Woolen Company as Mr. Bredbury started in the textile industry as a boy in the Washington Mills in 1889.

David R. Lawson, formerly Paymaster of the Wood Mill has been promoted to Cashier of the Shawsheen Mills and Phillips Blades of the Ayer Mills Pay Office, takes the position of Paymaster.

Arthur George, who some years ago was transferred from the Yarn Department at Boston to the Wood Worsted Mills, where he has recently been acting Superintendent of the French Spinning Department during the absence of Mr. Bredbury in Europe, has been appointed Assistant to the Agent.

The following have been made Overseers; Ralph Curtin, formerly Second-hand of the French Spinning Department of the Wood Mills, Overseer of Drawing.

David Archibald, Second-hand of the Twisting Room of the Ayer Mills, Overseer of Twisting and Winding.

William Harrison, Boss Machinist of the Ayer Mill, Master Mechanic,

Benjamin Babb, formerly Shipper in the Products Company Warehouse, Overseer of Shipping.

Henry Speak, Overseer of Mule Spinning.

Augustine F. Horman, Overseer of Carding and Ernest Howard, Overseer of Combing. - (The A. W. Employees Booster.)

The Shawsheen Mills unit was a modern concrete structure and contained over 850,000 square feet of floor space devoted to the manufacture of fine piece dyed worsted men's and ladies wear. Over twenty-five million pounds of grease wool was need each year to keep the wheels turning, and the 2600 employees busy. With the exception of wool scouring, all operations for producing finished worsted cloth from wool are performed in this mill. During WWII the company produced millions of yards of various woolen and worsted fabrics used in the several Armed and Auxiliary Services of the government. Shawsheen Mills also turned out a substantial amount of Worsted Tropicals, Gabardines, and Flannels.

Wool to cloth process; Extrapolated from American Woolen Co. page in Andover, What it Was, Whait it Is, 1946;

Wool is first scoured, passed through opening machines which knocks off foreign matter in the wool fiber, then blown through a pipe line to the Card Room. Card room mixes and and forms the wool into preliminary condition and shape for the Combing process. Combing sorts out the short fibers and the longer fibers are laid parallel to one another and formed into what is called "Top".

The Top then goes to the Drawing Room where, in several operations, it is drawn through rotating rolls of different speeds forming smalls continuous strands called Roving, which are then ready for the Spinning into yarn.

The Spinning Department twists the yarn to add strength so the yarn will pass though the ensuing operations with a minimum of breakage. Several supplementary operations continue the process, Winding, Spooling and Twisting, follow and the yarn is then placed onto beams and is ready to go to the looms for Weaving. In the loom the threads are set up into frames called harness, according to a selected pattern, plain or patterned. After Weaving, imperfections are repaired by hand. These are the Burchers and Menders.

The cloth then goes to the Finishing Room and washed to remove any dirt or foreign matter. The Dyeing process is next., only using the fastest dyes. The cloth is then dried and returned to the Finishing Room for a process through shearing and pressing. After a final inspection, the cloth is rolled up an papered for shipping.

Competition from the Southern States saw a decline in business after WWII and on Feb. 17, 1955 the American Woolen Company voted to merge with Textron, Inc of Providence, RI established on April 16, 1928, and Robbins Mills, Inc. of New York established on Jan. 27, 1927. The merger took place on Feb. 23, 1955 and was approved as a new company by Massachusetts Court on Feb. 28, 1955 under the new name of Textron American, Inc. The name was then changed to Textron, Inc. a few months later. The Shawsheen Mills were then sold to Raytheon Manufacturing Co. of Lexington, MA in 1956.

See Brickstone Square.

Bibliography/References:

Essex County Registry Deeds, Salem, MA

Essex Northern Registry Deeds, Lawrence, MA

Andover Historical Society files

Andover Historical Society files - See Area Form - Shawsheen for a complete bibliography.

Maps of Shawsheen Village 1920-1926 - American Woolen Co. - Collection of the Andover Historical Soc.

Town Crier: Directory of Shawsheen Village, 1922

Andover Street Directories

Andover Townsman

Andover, What it Was, What it Is - 1946

Mills, Mergers and Mansions, by Edward Roddy 1982

Molloy, Peter; The Lower Merrimack River Valley, an Inventory of Historic Engineering and Industrial Sites, sponsored by Merrimack Valley Textile Museum and Historic American Engineering Record/ Washington, National Park Service, Washington, 1976.

Andover Maps, 1852, 1872, 1888, 1906, 1926

See Map plan #704 - American Woolen Company - Sept. 1927

Map plan #708 - Nov. 1927 - AWCo.

Plan #826 - Sept. 1930 - Shawsheen Dairy - AWCo.

Plan #2680 - lot 6

Plan #3511 - July 1957 - NE Milk Producers' Association Parcel A & B

Plan #4385 - July 1961 - B&M Railroad - b. 948 p. 226

Plan #4975 - Dec. 1960 - Raytheon Park

Plan #9209 - Jan. 19, 1983 - Parcel C

Plan #11218 - July 29, 1988 - lot 2

Plan #11742 - May 8, 1989 - lots 3-4-5

Bailey Bridge - Oct. 31, 1961 - b. 917 p. 465

Bailey Bridge - May 23, 1969 - b. 946 p. 63

Owners; Along the River west of York St.

John Smith & Peter Smith – Dec. 29, 1841 –b. 335 leaf 99

Smith & Dove Manufacturing Co. – July 1, 1864 - b. 677 leaf 259 Salem deed

Robert Braisford, General Degreasing Co. – July 21, 1902 – b. 197 p. 32

Beacon Trust Company. – Dec. 23, 1904 – b. 217 p. 80

Daniel C. Smith –Mar. 28, 1909 – b. 258 p. 446

Arlington National Bank – June 11, 1909 – b. 274 p. 565

James E. McGovern – July 17, 1909 – b. 275 p. 400 – mgt sale

Henry P. Binney, Trustee of A. W. Co. – Aug. 14, 1909 - b. 277 p. 310

Haverhill St. and east of York -

American Woolen Co. of NJ - Feb. 15, 1916 - b. 361 p. 411

American Woolen Company, Wm. M. Wood Pres. - Dec. 30, 1920 - b.435 p. 215 parcel 2a

American Woolen Company - Dec. 23, 1931 - b. 562 p. 323

American Woolen Company - Feb. 17, 1955 - Vote to merge

American Woolen Company - Feb. 28, 1955 - b. 809 p. 204 - merger

Textron American, Inc. - of Providence, RI - Feb. 23, 1955

Textron, Inc. - Dec. 13, 1956 -

Raytheon Manufacturing Co. - Feb. 20, 1956 - b.

Raytheon Company - Apr. 28, 1961 - b. 935 p. 206

Shetland Properties - Andover - Mar. 29, 1971 - b. 1168 p. 131 & 133

Andover Mills Realty Limited Partnership - Dec. 24, 1986 - b. 2389 p. 194

Niuna Grafton, Inc. - Oct. 12, 1988 - b. 2835 p. 298

Andover Mills Realty Limited Partnership - Feb. 1, 1990 - b. 3087 p. 345

Andover Mills LLC - Apr. 14, 2003 - b. 7694 p. 252 - 267

Trans-Western Brickstone Square, LLC

A SLAN III Brickstone Sq. LLC - Nov. 28, 2005 - b. 9912 p. 130

New Brickstone Office , LLC - Sept. 30, 2014 - b. 13994 p. 71

Inventory Data:

| Street | Haverhill St |

| Place | Shawsheen Village - Frye Village |

| Historic District | Shawsheen Village NRH District |

| Historic Name | Shawsheen Mills of the American Woolen Co. |

| Present Use | Industrial electronics plant |

| Original Use | Textile factory |

| Construction Date | 1921 |

| Source | ERDS, ENRDL, assessers' rec./style-njs |

| Architectural Style | Other |

| Architect/Builder | Winfield B. Knowlton - architect /Turner Construction Co. |

| Foundation | stone/brick/concrete |

| Wall/Trim | Brick and reinforced concrete |

| Roof | asphalt/gravel- flat |

| Outbuildings / Secondary Structures | Warehouse - dye house |

| Major Alterations | Feb. 1956 - Raytheon Corporation converts woolen mill to electronics production. Mar. 1971 - Shetland Properties - converts to multi-business park Andover Mills Realty Limited Partnership Dec. 4, 1986 - Upgrades interior and exterior creating Brickstone Square. Mill number 4 demolished |

| Condition | excellent |

| Acreage | 25.5 acres |

| Setting | residential/commerical |

| Map and parcel | 35-27 |

| Recorded by | Stack/Mofford, James Batchelder |

| Organization | Andover Preservation Commission |

| Date entered | 1975 - 1977, 9/02/2015 |