Architectural Description:

Georgian Revival - This building was a handsome structure for a milk processing center. Close examination of the west front facade and south facade shows that they were originally similar in design. The south facade on the top floor reveals four rectangular windows, now bricked in, flanked by two arched windows at each end with decorative grill work. A similar fate with the windows on the first floor. Just key stones and lintels remain as to their location.

The front facade is wider with seven windows flanked by two arched windows on the top floor with decorative grills. The main entrance is also an arched doorway with classical surround. Roof pediment above eave banding has decorative car-touches and swags.

Historical Narrative:

Themes: Agricultural, Architectural, Community development, Industry, Social / humanitarian

Original owner: American Woolen Company

The site is historically significant as it was the location of the first Mill building of business partners, John Smith, Joseph Faulkner and Warren Richardson. The mill was constructed in 1824 for the manufacture of cotton machinery. After the deaths of both John Smith's partners, John with his brother Peter Smith and friend John Dove switch over to flax production to linen threads in 1833, the first such mill in America under the name Smith-Dove Company. This later became the Smith & Dove Manufacturing Co.

Prior to Shawsheen Village this area was known as Frye Village. Shawsheen Village was named after the Native American name for the river Shawshin, which means Great Spring. All the streets in the new Village were named for Castles & Cathedrals in Great Britain. Tantalon Castle is a semi-ruined mid-14th-century fortress, located 3.1 miles east of North Berwick, in East Lothian, Scotland. It was a formidable stronghold that stands on a cliff overlooking the Firth of Forth. The last medieval curtain wall castle to be constructed in Scotland, it was the seat of the Douglas Earls of Angus, one of the most powerful baronial families in Scotland.

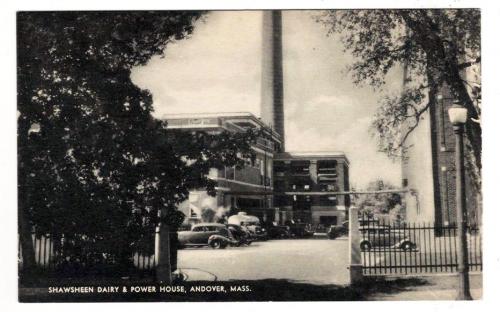

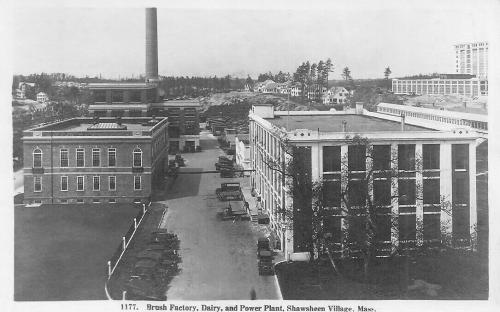

The Shawsheen Creamery Building - Shawsheen Dairy and later Yankee Milk is in the Shawsheen Village National Register Historic District, surveyed in 1975 and created in 1979. It was designated a National Register Historic District in 1980 by the Massachusetts Historical Commission, of the Commonwealth of Massachusetts.

The Shawsheen Creamery was built in 1922 to service the five American Woolen Company farms in West Andover. Two Ayrshire Dairies, Wild Rose Farm and the Clover Farm on Lowell Street, Shawsheen Stock Farm on Argilla Rd. and two farms on High Plain Rd. all managed by American Woolen Co., but owned by the Arden Trust of William Wood. Fresh milk was brought in, sterilized, bottled and then sold about 8000 bottles per day, to the residents of Shawsheen Village. They also supplied the Balmoral Spa, Shawsheen Manor and the Shawsheen Cafeteria with fresh milk, cream, butter, cheese and ice cream. This creamery also provided milk for the mill restaurant in Lawrence and adjacent communities,The building was constructed in the Georgian Revival style. The architects were most likely Adden & Parker of Boston. The Shawsheen Creamery enjoyed a successful business in this location.

The following article in the Andover Townsman, Mar. 9, 1923 gives a complete description of the building and milk processing.

SHAWSHEEN CREAMERY - Model Village Boasts the Most Sanitary and Up-to-date Plant in the Country.

"Without any question no more sanitary and modern creamery can be found in this country than that which is located here in Shawsheen Village. Is has been designed to take care of the entire output of the five fine dairy farms of the American Woolen Company, all of which are situated within a comparatively short distance of this model creamery.

This building which has two stories and basement is 90 feet by 72 feet and faces on Tantalon road just south of the power plant. The superstructure is of steel reinforced with concrete with a solid veneer of brickwork, conforming to the Georgian Colonial style of architecture, which is in keeping with the surrounding buildings forming the main group in the central part of the village. A sufficient number of windows on all sides furnishes ample light. The interior finish of all rooms where machinery or equipment is installed is of glazed white enameled tile on the side walls, tile floors and white enameled ceilings. In fact practically all exposed part of the apparatus and equipment are white enameled to insure the utmost cleanliness.

At the rear of the building is a large receiving and delivery platform of U-shape on the same level as the first floor made into the main structure, the second floor thus forming a roof over this platform.

Milk is received twice daily form the dairy farms where it has been previously passed through aerators. It is unloaded at the left platform and delivered from the cans into the milk weighing room. Here are located two glass-lined weighing vats each of 50 gallons capacity. From the weighing vats it flows by gravity into another glass-lined vat beneath, from which a motor-driven pump delivers all the milf to a large 800 gallon glass-lined tank on the upper level. All of the containers throughout the creamery into which the milk is conducted are glass-lined and so constructed that they may be through;y cleansed and sterilized.

After the milk has been emptied into the weighing vats the cans are immediately removed to the can washers where they are rinsed, steam sterilized, and dried with sterilized hot air, before being taken back to the farms.

Before going into the process by which all milk is treated before being delivered to the consumer we must mention the treatment given the milk bottles. These are delivered in cases into a York No. 7 milk bottle and case washer. These cases with the bottles are put into one end of this large washer where they are most thoroughly rinsed by a spray under pressure from both top and bottom. They then undergo two washings, after which they are steam sterilized and rinsed with hot water.

A conveyor delivers these cases of bottles onto trucks which take them to a conveyor in front of two Milwaukee bottlers and cappers. Each bottle is automatically filled and capped without being touched by hand. The cases are then filled and conveyed into the mile refrigerator from which place they can be readily loaded into the delivery trucks at the rear platform.

After milk which is received at the creamery has been delivered to the large 800 gallon reservoir on the upper level, that which is to be pasteurized and sold as milk passes through a pre-heater thence to a De Laval Centrifugal Clarifer which removes every vestige of sediment or solid matter which may have been in the milk. From this point the milk goes into one of three pasteurizers each of 350 gallons capacity and having recording thermometers. A constant temperature of 145 degrees F is maintained for 30 minutes. The next operation is to cool the milk as quickly as possible from 145 to 45 degrees. This is accomplished by passing it over a tubular cooler having a maximum capacity of 2800 quarts per hour. From the cooler it goes into the 300-gallon glass lined equalizer where the temperature is held a 45 degrees and from this point the thoroughly pasteurized milk is taken out and bottled by the automatic bottling machines.

Milk from which cream is to be extracted is preheated and passed through a De Laval Cream Separator into a 350-gallon cream pasteurizer. Cream is then passed through the tubular coolers and bottled exactly the same as milk. Another pasteurizer is available for use in making buttermilk.

On the second floor is a large butter room capable of producing 1000 pounds daily. Cream to be used for butter is conducted into one of two large cream pasteurizers and ripeners and a motor driver centrifugal pump delivers it from here to either the large or small motor-driven churn. After churning the butter is handled and goes through the printing machine in the most sanitary manner to prepare it for transportation to the consumer.

In the butter room are also two 350-gallon containers for skim milk, which are pasteurizers as well, and this milk is used to make fancy cheeses.

All piping for conducting the milk and cream to and from the various containers is of two inch heavy copper, tinned on inside and outside, and heavily nickelled outside as well. These sections of piping are so constructed with quick acting couplings that they may be readily removed. After each process this piping is removed to a large tank where it is brushed, thoroughly washed with a solution, rinsed with hot water and then sterilized with live steam before being returned and connected up.

On the floor above the main entrance is an observation room from which, through windows, practically all of the equipment above described may be seen in operation. One is much impressed with the spotless white appearance of all the apparatus and work rooms. Shower baths for men, a restroom for women, in fact everything necessary for the most sanitary and efficient operation of a model creamery is provided.

The refrigeration plant located on the north end of the first floor consists of two 20-ton Frick ammonia compressors, one of which is always held in reserve. These furnish the power for producing the necessary degrees of cold in a most efficient compression system of refrigeration.

In the northwest corner of the first floor a laboratory and main office are located. In the laboratory is installed the very latest improved Mojonnier equipment for testing milk solids. This is the most accurate test yet devised and consists of the necessary apparatus to break apart and analyze milk solids by use of ether. This laboratory also has a culture cabinet where the mother culture is preserved and increased for use in butter making. Her are also to be found accurate weighing scales and means for detecting improper sterilization of equipment.

One has but to make a visit to this plant to be thoroughly convinced that we have here the most elaborate, sanitary and up-to-date creamery which it is possible to build."

After the death of William M. Wood on Feb. 2, 1926 most of the residential and commercial buildings were then sold. Some were held by the Wood family in the "Arden Trust" and others with the American Woolen Company, which had been deeded the properties in December 1920. The A.W.Co. Board of Directors authorized its President, Lionel J. Noah, to deliver all deeds, as deemed necessary to the Textile Realty Co. for sale on Dec. 29, 1931. This property however was sold by the company in 1930 to Edward C. Williams.

Edward C. Williams was the manager in of the Shawsheen Dairy from 1923 - 1935. On December 18, 1930, Edward Williams purchased the building and five months later placed the deed with the Shawsheen Dairies, Inc. on May 15, 1931. Edward, wife Harriett and sons Edward C. Jr., Raymond C. and Russell lived in the Village first at 50 York, then 2 Argyle before purchasing 102 Burnham Rd. Edward retired in 1935.

Thomas P. Kelley followed Williams as the Proprietor (1935-1940) of the Dairy. It is not known if the Great Depression had any effect on the milk business but in September 15, 1939 the Shawsheen Dairy took a $40,000 mortgage with the Arlington Trust Bank of Lawrence. Perhaps to upgrade the equipment.

AT- October 17, 1940 -p7 - Full page advert for Shawsheen Dairy, photo of building & truck.

Shawsheen Dairies, Inc. went Bankrupt in August of 1941. Martin Witte was named trustee of the estate assets. Edward Popell of Boston was engaged in the process on Aug. 18, 1941. The Shawsheen Dairies, Inc. Aug. 18, 1941, with permission from Arlington Trust, sold off all the milk processing equipment in the building to H.P. Hood & Sons, Inc. on Feb. 4, 1942 and striped the building of all equipment except what was specifically specified to remain. The deeds give a long list of what was sold and an insight as to the scope of the milk processing business. The building also included a lunchroom and soda counter where ice cream was sold to patrons.

The building was then sold to Helen C. Collins on May 18, 1942. The New England Milk Producers Association purchased the building on Feb. 18, 1943. Francis L. Foley, then District manager took over in 1943 - 1947. Francis and wife Ellen lived a 3 Yale St. John S. Adams of Wakefield followed Foley 1947-1950. Then S. Franklin McQuestion of No. Andover took over as manager in 1951.

New England Milk Producers Association then continued the milk processing and distribution center in the building. On Plan map #3511, surveyed in June 1957, the 13,190 square foot lot B, which had been once a lawn in front of the Shawsheen Creamery building, was purchased from Hardy Brush Corp. on July 30, 1957. A new office building was then constructed now 12 Haverhill St. the New England Bank the leasing tenant.

New England Milk Producers Association later sold to Yankee Milk, Inc. of Connecticut, Louis P. Longo, Pres. on July 12, 1972 which included the new and old dairy buildings and the lot along Tantalon Rd. In the summer of 1977, Yankee Milk announced its plans to move the company to North Andover. The property was then sold to Agri-Mark, Inc. Paul Johnson, Pres. on July 16, 1980.

Agri-Mark is a Dairy Farmers Cooperative who markets member's milk and products. It continues in the region of New England and New York with four processing plants, Agri-Mark and Cabot Cheese are two of the largest members. Two years later on May 26, 1982 Augustine "Gus" P. Sheehey purchased the property. Gus was one of eight business partners of the Shawsheen Village Commerce Partnership of Boston who then took ownership of the buildings on June 12, 1985. This transaction included the two former milk buildings and the Hardy Brush Factory building at 16 Haverhill St.

The Yankee milk building at 12 Haverhill St. was renovated and leased and the Hardy Brush factory was divided up into professional office space. The former Shawsheen Creamery building remains boarded up waiting for redevelopment.

Bibliography/References:

See Area Form - Shawsheen - for a complete bibliography

Essex County Registry Deeds, Salem, MA

Essex Northern Registry Deeds, Lawrence, MA

Andover Maps, 1852, 1872, 1888, 1906, 1926

Andover Street Directories

Andover Townsman

Mills, Mergers and Mansions, by Edward Roddy 1982

See Map plan #704 - American Woolen Company - Sept. 1927

#708 - Nov. 1927 - AWCo.

Plan #826 - Sept. 1930 - Shawsheen Dairy - AWCo.

Plan #3511 - July 1957 - NE Milk Producers' Association Parcel A & B

Plan #9209 - Jan. 19, 1983 - Parcel C

Owners;

John Smith & Peter Smith – Dec. 29, 1841 –b. 335 leaf 99

Smith & Dove Manufacturing Co. – July 1, 1864 - b. 677 leaf 259 Salem deed

Robert Braisford, General Degreasing Co. – July 21, 1902 – b. 197 p. 32

Beacon Trust Company. – Dec. 23, 1904 – b. 217 p. 80

Daniel C. Smith –Mar. 28, 1909 – b. 258 p. 446

Arlington National Bank – June 11, 1909 – b. 274 p. 565

James E. McGovern – July 17, 1909 – b. 275 p. 400 – mgt sale

Henry P. Binney, Trustee of A. W. Co. – Aug. 14, 1909 - b. 277 p. 310

American Woolen Co. of NJ - Feb. 15, 1916 - b. 361 p. 411

American Woolen Company, Wm. M. Wood Pres. - Dec. 30, 1920 - b.435 p. 215

Edward C. Williams - Dec. 18, 1930 - b. 557 p. 35

Shawsheen Dairies, Inc. - May 15, 1931 - b. 559 p. 336

Arlington Trust - Sept. 15, 1939 - mtg.

Shawsheen Dairies, Inc, estate Bankrupt, Martin Witte, Trustee 1941

Edward Popell of Boston - Aug. 18, 1941 -

Shawsheen Dairies, Inc. Aug. 18, 1941 - b. 644 p. 371

H.P. Hood & Sons, Inc. - Feb. 4, 1942 - b. 651 p. 307 - all equipment

Helen C. Collins - May 18, 1942 - b. 651 p. 314 - building

New England Milk Producers Association - Feb. 18, 1943 - b. 656 p. 119

Hardy Brush Corp. parcels A & B map #3511 to NE. Milk Producers Assoc.

New England Milk Producers Association - July 30, 1957 - b. 858 p. 458 - parcels A & B

IT Yankee Milk, Inc. of Connecticut, Louis P. Longo, Pres. = July 12, 1972 - b. 1197 p. 162 (3 parcels)

Agri-Mark, Inc. Paul Johnson, Pres. - July 16, 1980 - b. 1443 p. 254 -

Augustine P. Sheehey - May 26, 1982 - b. 1583 p. 190

Shawsheen Village Commerce Partnership of Boston - June 12, 1985 - b. 1986 p. 255

Union National Bank of Lowell,

F.D.I.C. Receiver of Bank of New England - July 31, 1986 - b. 2266 p. 199 -rec. 8/8/1986

Lease & Rental Management Corp. - Jan. 6, 1994 - b. 3956 p. 115

Windham Realty Limited Liability Co. - Nov. 22, 1994 - b. 4168 p. 210

Inventory Data:

| Street | Tantallon Rd |

| Place | Shawsheen Village - Frye Village |

| Historic District | Shawsheen Village NRH District |

| Historic Name | Shawsheen Dairy Building |

| Present Use | vacant |

| Original Use | Shawsheen Creamery - Yankee Milk |

| Construction Date | 1922 - 1923 |

| Source | ERDS, ENRDL, assessers' rec./style-njs |

| Architectural Style | Georgian Revival |

| Architect/Builder | Adden & Parker of Boston |

| Foundation | concrete |

| Wall/Trim | brick/limestone |

| Roof | asphalt/gravel- flat |

| Major Alterations | small addition to the south side, two bay garage on north side, many original windows have been in-filled with matching brick, north wall vents into window frames. |

| Condition | poor |

| Acreage | 0.359 acre |

| Setting | commercial/business |

| Map and parcel | 35-6 |

| Recorded by | Stack/Mofford, James Batchelder |

| Organization | Andover Preservation Commission |

| Date entered | 1975-1977, 8/31/2015 |